Vessel Management System (VMS) is the perfect automation solution for medium to large size vessels

Features

The Mega-Guard Vessel Management System (VMS) is an advanced system for perfect ship automation for medium to large size ships. Mega-Guard VMS is a modular system which can be tailor made based upon ship’s automation requirements. Often realized functions with Mega-Guard VMS include the following:

The Mega-Guard Vessel Management System (VMS) is an advanced system for perfect ship automation for medium to large size ships. Mega-Guard VMS is a modular system which can be tailor made based upon ship’s automation requirements. Often realized functions with Mega-Guard VMS include the following:

- Alarm and monitoring system

- Extension alarm system

- Valve, pump and fan control

- Cargo control and monitoring

- Tank gauging

- Fuel oil transfer

- Automatic ballasting

- Anti heeling

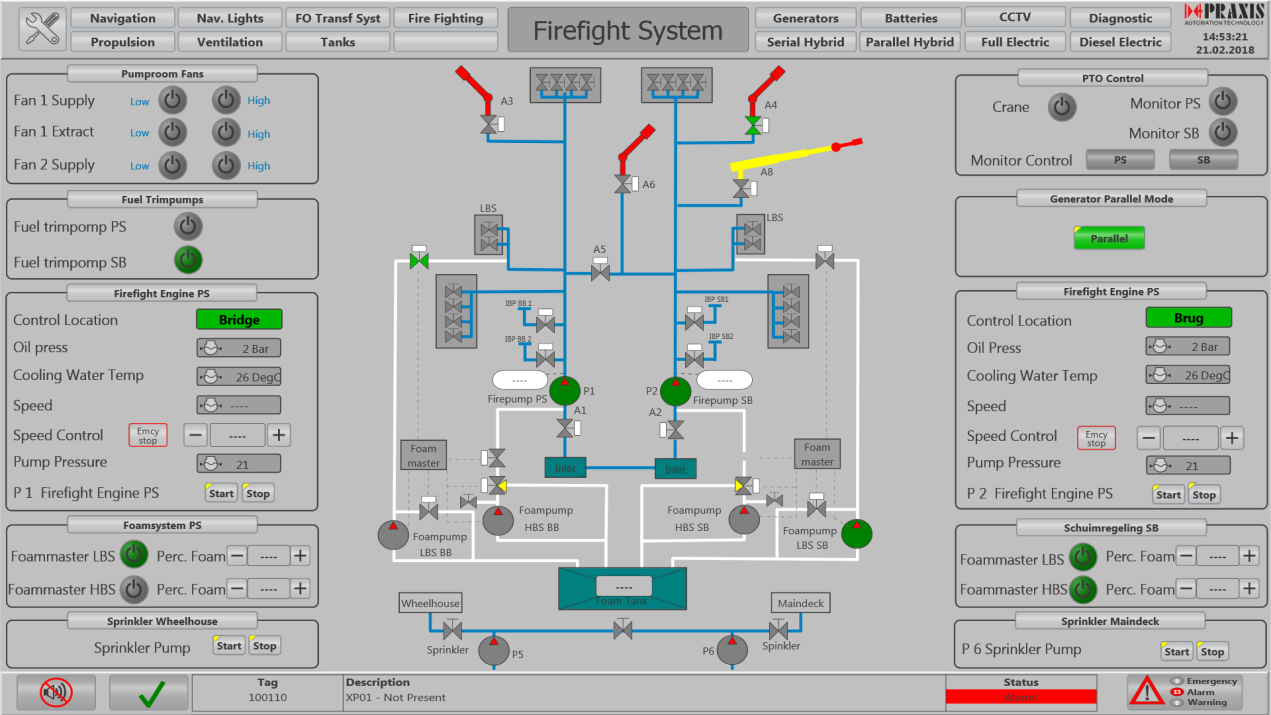

- Firefighting

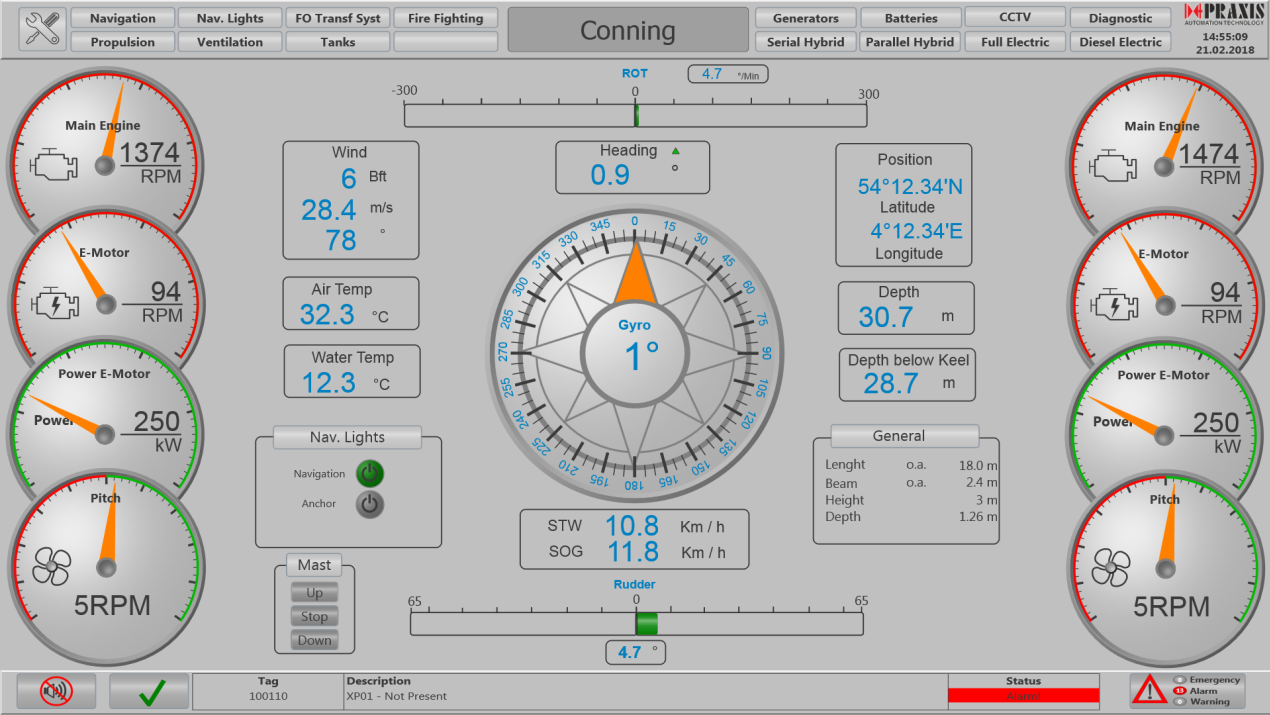

- Conning

- CCTV

- Etc.

In addition, Mega-Guard VMS can be extended with the following independent Mega-Guard systems as described in separate brochures:

- Alarm and monitoring system

- Extension alarm system

- Power Management System

- Propulsion Control System

- Dynamic Positioning System

- Integrated Navigation System

- Heading Control System

- BNWAS Watch Alarm System

- Navigation Light Control

- Wiper Control system

- Fire Alarm System

- Econometer

- Internet Fleet Managment

Mega-Guard VMS can also be easily integrated with the Mega-Guard Green Propulsion product line which consists of:

- Electric Steerable POD propulsor

- Electric Propulsion Motor

- Electric Fin Stabilizer

- Electric Winch

- DC Bus Generator

- DC Bus Battery Storage

- DC Bus Power Inverter

- DC Bus Distribution

Application

The Mega-Guard Vessel Management System is the most reliable and field proven automation system as can be found on the market and is built-up with the following components and features:

- Operator Workstations

Workstations are equipped with touchscreen and an integrated marine personal computer under Windows 10 embedded operating system. Solid state disk instead of hard disk is applied and multi-server structure ensures safety and reliability. The ruggedized Operator Workstations are available in touchscreen sizes ranging from 10” to 55”. The high definition widescreen Workstations are available with HD (1920×1080) and UHD (3840×2160) resolution. The Operator Workstation can be extended with a Trackpad and Trackball Operator Panel and a hard copy printer. - Control Processors

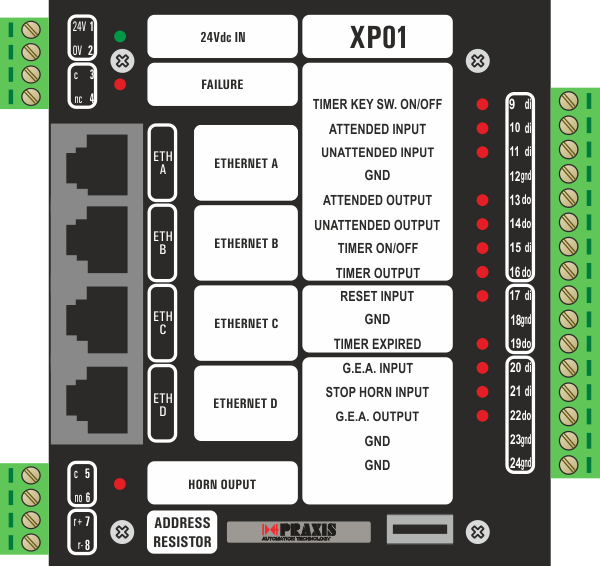

Control and monitoring logic (PLC) is executed by powerful Control Processors. Sensor inputs and actuator outputs are connected to I/O Modules. A Control Processor has four Ethernet ports and up to eight I/O Modules. A Control Processor is also able to communicate with external

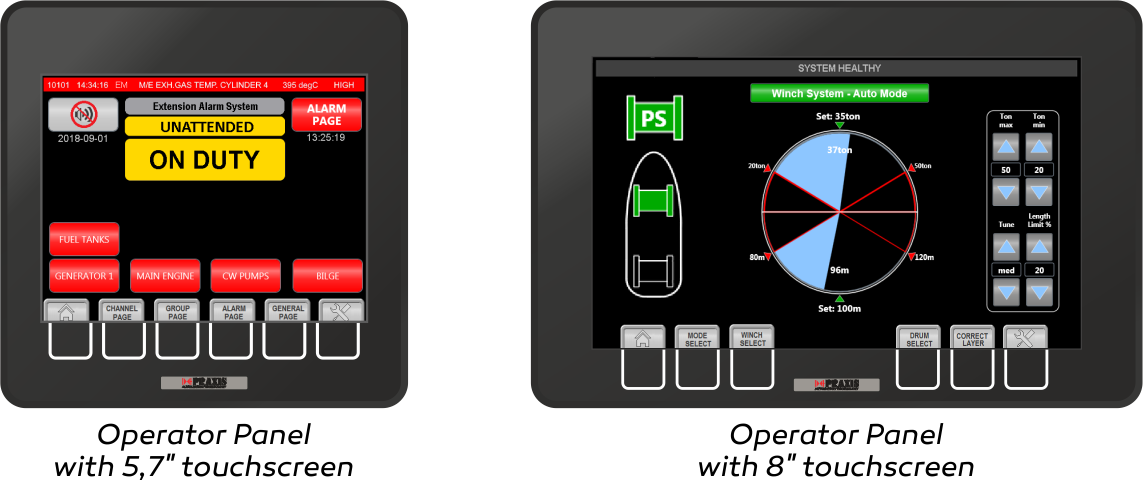

systems through multiple protocols over Ethernet, RS485/422 and Canbus communication links. Control Processors and I/O Modules are mounted on DIN rails inside cabinets, switchboards and consoles. - Operator Panels

Operator Panels combine local operation and control logic in one device. An Operator Panel is built-up with a 5.7” or 8” touchscreen and a built-in Control Processor which is able to communicate to up to eight I/O Modules. Example applications include Extension Alarm System, Power management System, Propulsion Control System and Fire Alarm System. The stylish Operator Panel is flush mounted. - Redundant Ethernet

Operator Workstations, Control Processors and Operator Panels are interconnected by redundant Ethernet link. Cabling with Star topology or Ring topology or a combination of Star and Ring topology is supported. - Configuration standard

Programming in accordance with international PLC programming standard IEC61131-3 (ST) and 3D graphic design in accordance with latest standards. - Type approval

Type approved by all major class classification societies such as Lloyds Register of Shipping, DNV-GL, American Bureau of Shipping, Bureau Vertitas, RINA, Russian Maritime Register of Shipping, CCS, NKK, PRS, KR etc.

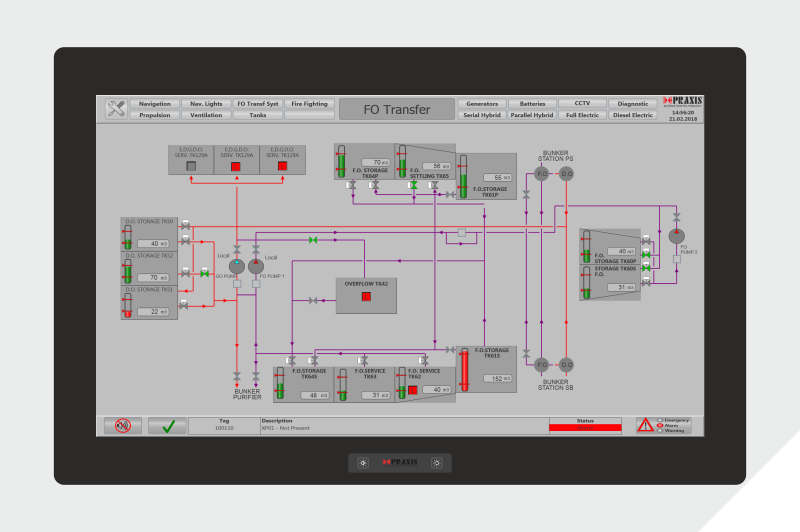

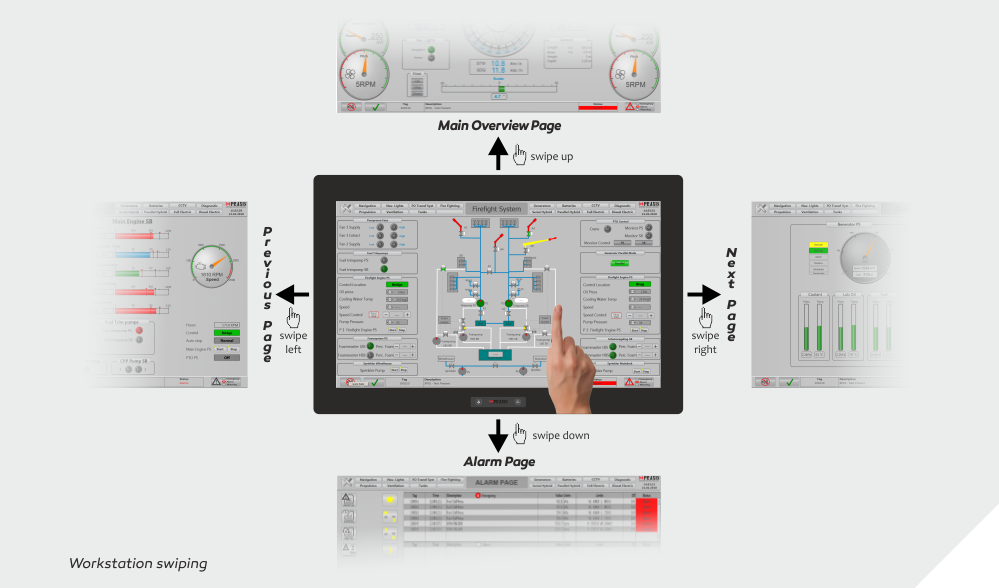

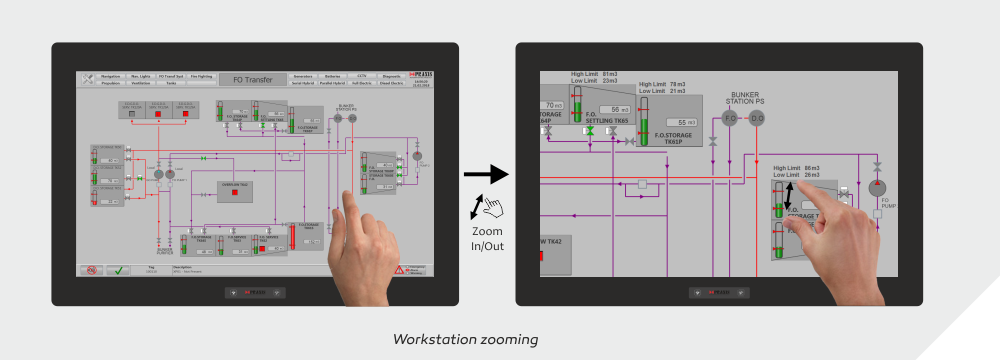

Swiping and zooming

Operator Workstations and Operator Panels are equipped with the latest 3D graphic software package for an intuitive and dynamic operation. The Workstation touchscreen allows for instance swiping in between pages and swiping to alarm list. The zooming function provides more detailed information regarding the zoomed-in area. Up to 4 layers of additional data can be presented depending on the zooming level. Pop-up menus give more detailed information regarding the selected device as well. The pop-up can be made in a realistic way (photo) so that it resembles the actual

to be controlled device.

The Extension Alarm System (EAS) is a highly reliable engineer calling system, which extends the Mega-Guard VMS for unmanned machinery space operation. On duty selection and engineer calling functions are executed on a dedicated mimic on the Workstation.

The dedicated mimic display on the Workstation contains the following fields:

- On duty selection

- Attended / unattended (manned/

- unmanned) engine room

- Engineer calling

- Patrol timer / engineer safety system (dead man timer)

EAS Operator Panels are installed in bridge and accommodation areas. They provide detailed alarm and on duty information on the 5.7” touchscreen. In addition the operator is able to select grouped data such as fuel tanks, main engine, generators etc for viewing. The touchscreen has an automatic sleep function and awakes again when an alarm is presented or when the touchscreen is touched.

Marine PC

The Workstation contains a built-in Marine PC. The Marine PC is also available as a separate product and this is used when a 3rd party monitor is applied. The Marine PC is very compact and can be bulkhead mounted. The Marine PC is available in two versions:

- Standard version with Intel quad core Celeron CPU at 2Ghz

- High performance version with Intel dual core I5 CPU at 3GHz

Both versions require extremely low power which guarantees a long life and a high mean time between failure. Solid state disks are available in ranges from 32GB (standard) to 256GB. The Marine PC is powered by 24VDC and contains relays outputs for failure indication and connection of an external horn.

VMS Market segments

The VMS Vessel Management System is applied in all type of ships. Three market segments are distinguished:

- Commercial ships

- Mega yachts

- Navy ships

VMS Workstations and Operator Panels for mega yachts are delivered with highly esthetic glass fronts and for commercial ships a metal front with pushbuttons is applied. Navy ships require a more robust VMS with higher shock and vibration resistance. In addition, navy ships require added functionality such as battle damage control.

VMS Workstations and Operator Panels for mega yachts are delivered with highly esthetic glass fronts and for commercial ships a metal front with pushbuttons is applied. Navy ships require a more robust VMS with higher shock and vibration resistance. In addition, navy ships require added functionality such as battle damage control.

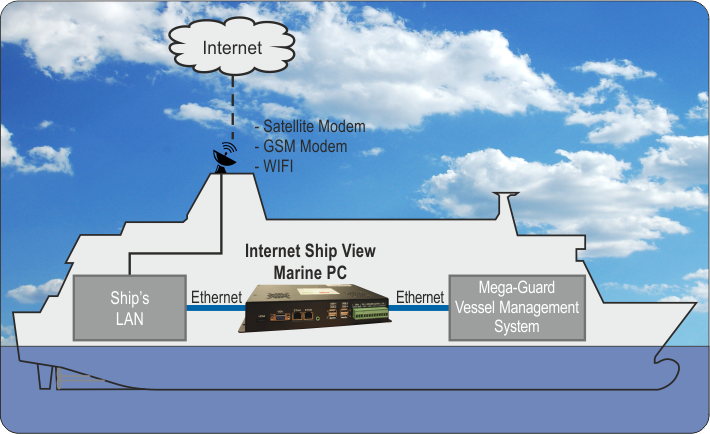

The Internet Ship View (ISV) system allows the ship owner (shore based) to view the VMS Vessel Management System (ship based) through the internet. Shore based standard PC’s with internet browser can be used to log-in to the VMS. This gives the same view as available on the ship based VMS Workstations. Praxis service department is also able to log-in in case of requests for commissioning support or trouble shooting. Secure communication and double log-in procedures are applied for protection against unauthorized users.

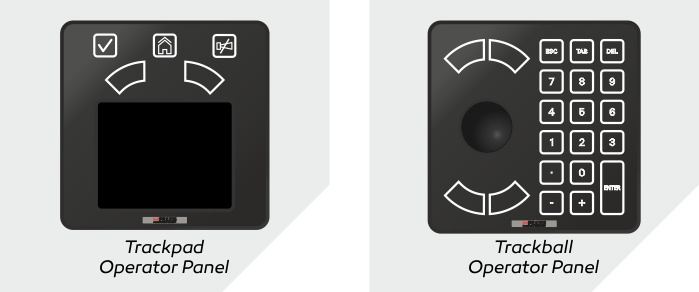

Trackpad and Trackball

Workstations can be operated with touchscreen. In addition to this two types of input devices are available: a Trackpad and Trackball Operator Panel. The Trackpad Panel offers a large trackpad for accurate and easy selection of the required function on the Workstation or monitor. The Trackball Panel is equipped with a trackball for function selection and a keypad is also integrated in this panel.

Workstations can be operated with touchscreen. In addition to this two types of input devices are available: a Trackpad and Trackball Operator Panel. The Trackpad Panel offers a large trackpad for accurate and easy selection of the required function on the Workstation or monitor. The Trackball Panel is equipped with a trackball for function selection and a keypad is also integrated in this panel.

Touchscreen Operator Panels are flush mounted in console, wall or cabinet. The 5.7” touchscreen Operator Panel is applied in commercial ships and mega yachts (glass version). The 8.4”touchscreen Operator Panel is mainly used for navy ships.

Example Mimics

Mimics are designed in close cooperation with ship owner

Colors, fonts and symbols are freely selectable

3D effects can be applied in the mimic

Intelligent zooming with additional info layers

CCTV cameras embedded in the mimics

Mounting & Dimensions